While at Autodesk, Woohoo had access to one of the best workshops in the world – Autodesk/Instructable’s Pier 9. With keys and code, Woohoo’s

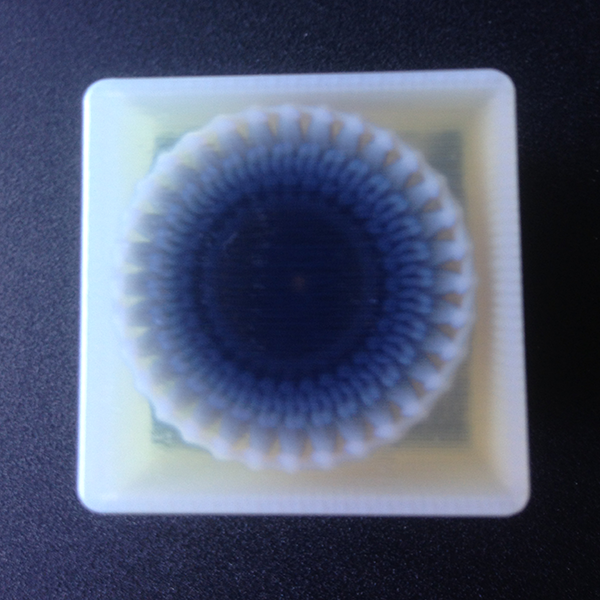

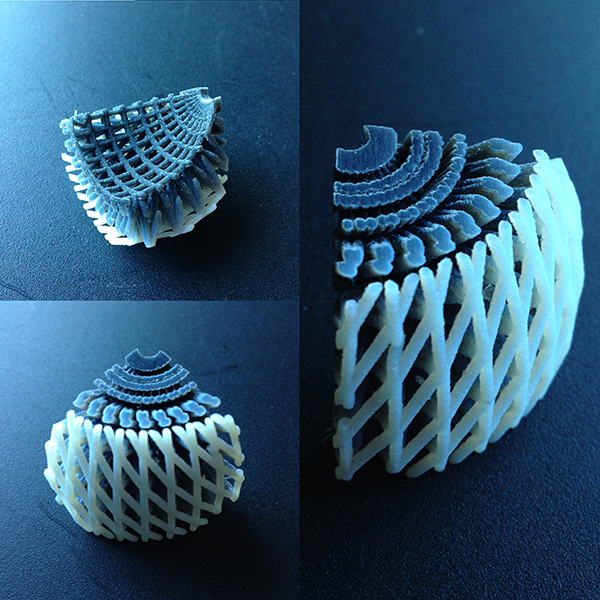

experimentations continued in the evening and weekends with a focus on additive manufacturing and specifically with functional-graded materials. In other words, applying gradients between theoretically 256 materials, in practice, up to 4 using the $250,000 (US) Object500 Connex 3d printers. Out of the box the Connex will print 2 materials that are either next to each other or as a full isometric blend that is seamless in all directions. The former has aesthetic and structural limitations – it doesn’t compare to the 3d prints in Neri Oxman’s Multiversités Créatives show with gradients. Structurally, wherever two materials meet, the bond is weak and the print often falls apart. The blends have more diverse characteristics, e.g., a blend can be stiffer than the most flexible example, but this material property is global. Woohoo wanted to match the creative beauty of Oxman’s work while at the same time explicitly define a variety in material properties like flexibility and strength via code on a moxel-by-moxel basis. This required a complete 180º approach that contradicts the approach most 3d modeling applications take. Woohoo worked early on with Amanda Ghassaei – from the 3d printed album fame, to understand her amazing experiments prior to this project. On the images above, Woohoo collaborated with the Project Dreamcatcher research team.