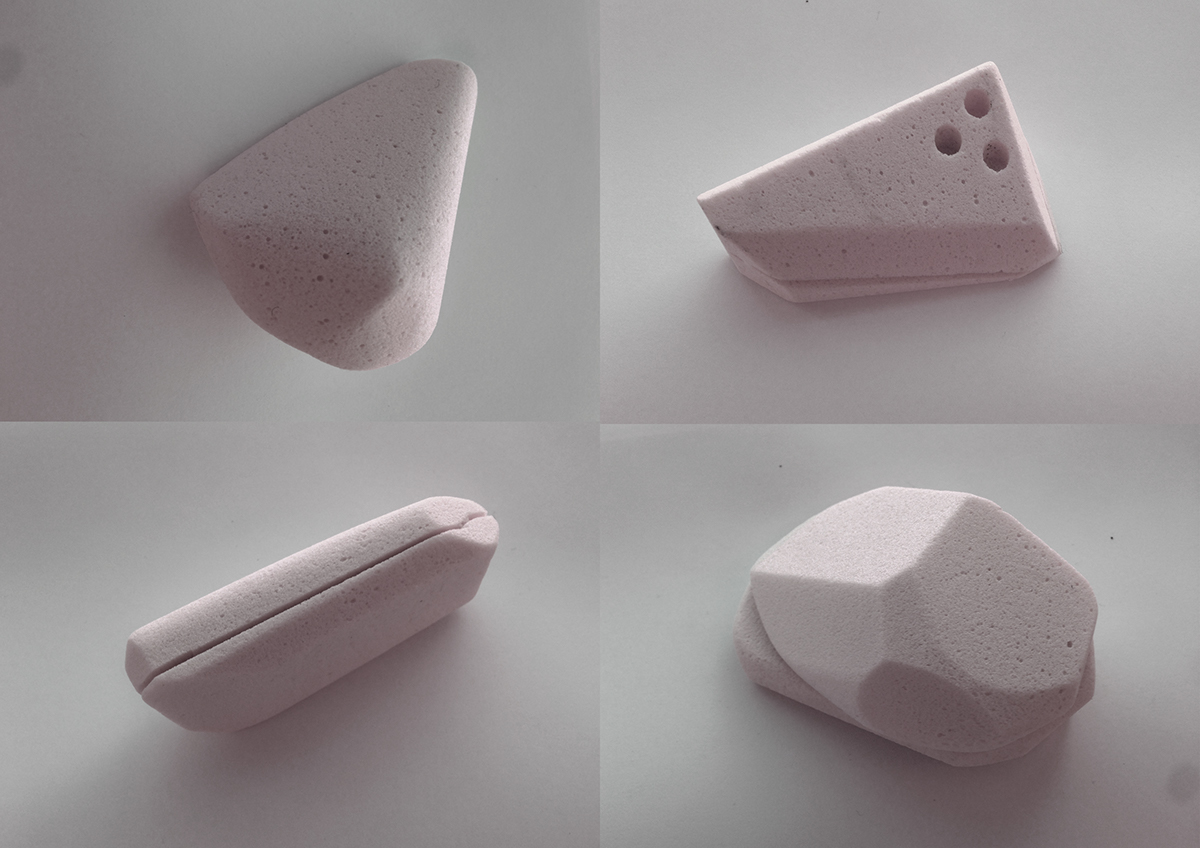

Figure 1

Essential to achieve the desired look and feel of a Moleskine concept was the process of yellow foam prototyping. Blocks of yellow foam were machined by hand to explore a range of tactile and ergonomic objects. It was important to create a form that was aesthetically pleasing from multiple orientations as well as easily portable for the user, much like a Moleskine notebook.

Inspiration can be obtained over years, months or even minutes; the exact method of which is not one of logic or reason. This Moleskine concept, for Fine Artists, attempts to rationalise the process of recording inspiration for later reference. By constantly taking samples of the sights, sounds and smells of everyday life, the user can observe their day at a later date for reinterpretation in traditional media.

Figure 2

Solidworks was used to transfer the ergonomics of the foam models into a reproducable CAD model. As the product was intended to accompany a group ensemble of Moleskine concepts, certain features of the design had to be a consistant throughout as well as paint finish.

Solidworks was used to transfer the ergonomics of the foam models into a reproducable CAD model. As the product was intended to accompany a group ensemble of Moleskine concepts, certain features of the design had to be a consistant throughout as well as paint finish.

Figure 3

The final stage of the concept development was to realise the virtual models in a 3D form. 3D printing was used to acurately achieve the desired curves of the design. The end presentation required multiple grades of sanding followed by spray coating and inserting components.

Figure 4

The end result was viewed by thousands of the general public, including industry professionals, at Made in Brunel 2013.