Schiphol Sound Barrier

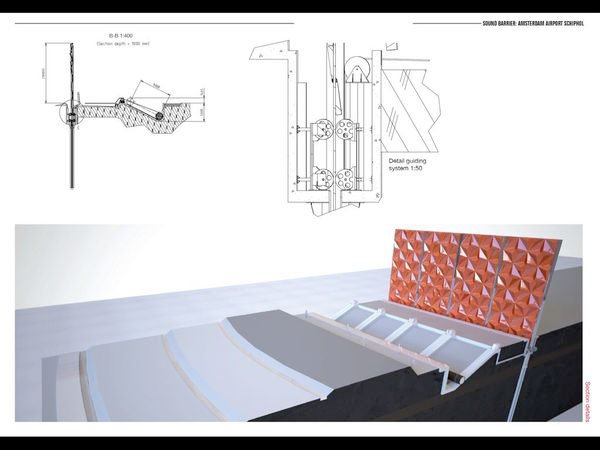

The Schiphol: Create a Barrier of Silence competition is nowcompleted. Various Architects and their international team receivedSecond Place in the Business category of the competition. Although theproject did not win one of the three main prizes we believe that wedelivered a solid project that answered Schiphol's call to innovationand sustainability. 9 companies and 27 individuals contributed to thisproject, and the high level of detail presented is a testimony to theirdedication and teamwork. “Dynamic Sculpture” is a design that will showcase Amsterdam AirportSchiphol’s commitment to innovation and sustainability. The iconicretractable wall achieves the required 7 dB sound reduction bycombining new materials, sustainable design, and a simple yetspectacular lifting solution. The proposed Environmental Hubeducational building and associated sustainable landscape park willcreate a world-class focus point for green technology and design.Together, these elements form a complex that would attract and educatevisitors while also actively cleaning the environment, generating greenenergy, and recycling airport waste. The competition parameters for sound reduction combined with therelevant airport and municipal regulations for building made it clearthat a dynamic structure was necessary to meet all of the programrequirements. The necessary ground noise reduction is achieved bydesigning a retractable wall of optimum height and closeness to therunway. Sound insulation of the wall is provided by the surface mass ofthe folded thermoplastic panels and by air-sealed connections when inthe upright position. The position and shape of the wall are formed inresponse to the changing noise levels along the length of the runway,at the beginning of the runway the wall is placed relatively closer. Itgently curves further away as the sound levels decrease with distance. The 2.1km undulating wall is faceted into 10m sections comprised of:folded horizontal thermoplastic panels, steel lifting poles, a rollingcounterweight connected to electric motors, and a base structure ofprecast elements. A high degree of prefabrication is specified toreduce on-site construction time and provide the necessary tolerancesbetween the pieces. All aspects of the project have been designed tominimize the disruption of airport activity and to ensure that it canbe built within the required 18 month construction schedule. The development of a rolling counterweight lifting system providesthe extreme reliability necessary for installations in the demandingairport environment. It also ensures a short conversion time forextension (3 min.) and retraction (1 min.) of the wall. The rollingcounterweight on rails provides a spectacular visual element in thepark and ensures the synchronised lifting of the wall. A redundantsystem of motors combined with a high mechanical efficiency and lowfriction moving components ensures that the wall will not get stuck inthe up position, even under high wind loads. The mechanical nature ofthe counterweight connection of the wall to the counterweight ensuresthat the wall can be lifted and retracted, even in the extreme case of10% motor failures. The proposed landscape park would provide an educative layout ofdifferent environmental technologies on display for the public, as wellas the production of electricity via solar, bio-gas, and bio-fuelproduction. The Hub Park creates a mini polder landscape wheredifferent technologies can be demonstrated, whereas the larger parkarea would be used for the cleaning of de-icing fluid, generation ofelectricity, and recycling of organic waste. Overall the park wouldprovide a new public promenade for local residents, visitors, and planespotters alike.